altadata

New Member

- Messages

- 16

- Reaction score

- 0

- Points

- 0

Hi

I have 2 problems similar in nature.

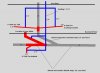

1) I need to install a Y fitting in a already existing 3 inch vertical pipe that runs from the basement floor up into the first floor.

If I cut this pipe, how can I insert the Y fitting, since I cannot move the upper part or lower part of the pipe?

2) I need to install a Y fitting into an already existing 3 inch horizontal pipe underneath the basement floor. If I cut this pipe, ow can I insert the Y fitting into the pipe, since I cannot move the left and right parts of the pipe?

Forgot to mention - all are plastic pipes.

Thanks.

I have 2 problems similar in nature.

1) I need to install a Y fitting in a already existing 3 inch vertical pipe that runs from the basement floor up into the first floor.

If I cut this pipe, how can I insert the Y fitting, since I cannot move the upper part or lower part of the pipe?

2) I need to install a Y fitting into an already existing 3 inch horizontal pipe underneath the basement floor. If I cut this pipe, ow can I insert the Y fitting into the pipe, since I cannot move the left and right parts of the pipe?

Forgot to mention - all are plastic pipes.

Thanks.