EthylOH

Member

Hi all,

I just plumbed in the shower for my bathroom. It looks terrible, but no leaks on 24 joints.

One thing that concerns me is the drop elbow line in the picture below:

When I was sweating the drop elbow, I had the 90 degree fitting pulled horizontal towards me so that I could keep the torch away from the blocking. Stupid me forgot that tinning flux in the fitting actually caused the 90 degree joint to be soldered at that angle. I tried to push it back as best I could with a scorching hot pipe, but it ended up sticking out a half inch, such that the nipple will be at a 45 degree angle when the trim is installed. After thinking it over for 10 minutes, I recovered the joint in flux, grabbed a pair of vise grips, and reheated the joint 'till I could move it in place. It took a lot of force to turn it (I could hear a "pop" when the existing solder released it), and then I added a bunch more solder.

The fitting doesn't leak, but should I be worried about it being a ticking time bomb in the future? This will be in a dividing wall between the tub and shower with NO access port, so a leak would be catastrophic.

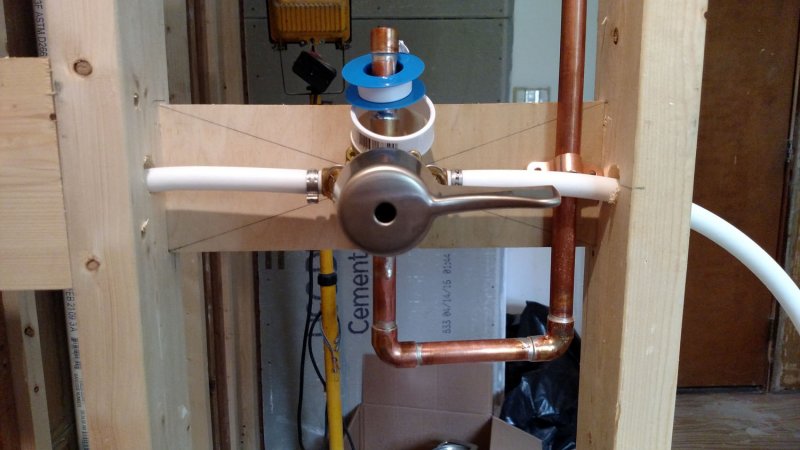

Here are the other pics so you can see how I get more solder all over the place. Also, I know I scorched some of the blocking, but I had a fire extinguisher right next to me.

I just plumbed in the shower for my bathroom. It looks terrible, but no leaks on 24 joints.

One thing that concerns me is the drop elbow line in the picture below:

When I was sweating the drop elbow, I had the 90 degree fitting pulled horizontal towards me so that I could keep the torch away from the blocking. Stupid me forgot that tinning flux in the fitting actually caused the 90 degree joint to be soldered at that angle. I tried to push it back as best I could with a scorching hot pipe, but it ended up sticking out a half inch, such that the nipple will be at a 45 degree angle when the trim is installed. After thinking it over for 10 minutes, I recovered the joint in flux, grabbed a pair of vise grips, and reheated the joint 'till I could move it in place. It took a lot of force to turn it (I could hear a "pop" when the existing solder released it), and then I added a bunch more solder.

The fitting doesn't leak, but should I be worried about it being a ticking time bomb in the future? This will be in a dividing wall between the tub and shower with NO access port, so a leak would be catastrophic.

Here are the other pics so you can see how I get more solder all over the place. Also, I know I scorched some of the blocking, but I had a fire extinguisher right next to me.