Robert Gray

Member

Maybe it's too early for me......

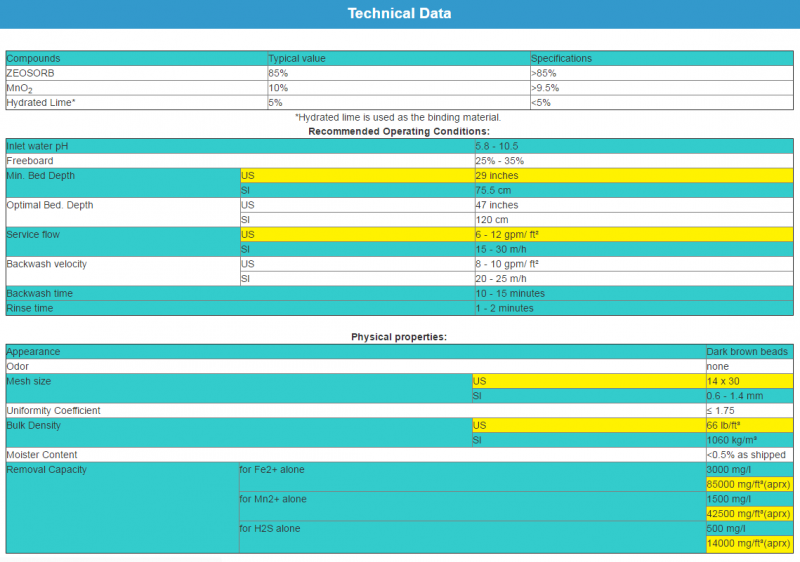

I can't wrap my head around the below information I found on Katalox Light.

Background: I have a shallow well that produces ~5.45gpm. I plan to upgrade my treatment system and am looking for media that requires a backwash rate close to what my well can provide. Below is what I found on Katalox....

Source: http://watchwater.com/katalox_light/katalox_light.php

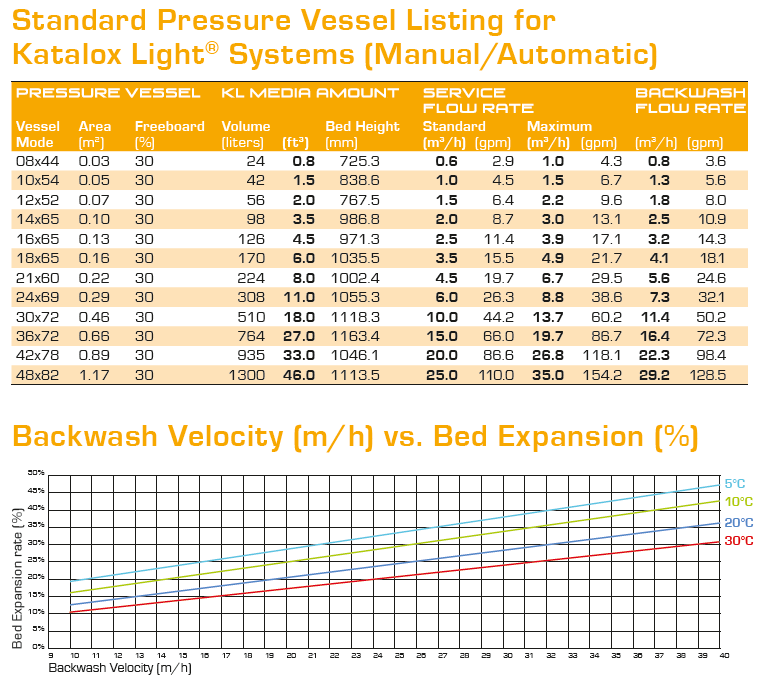

But, I also found the following from the same site:

Source: http://watchwater.com/katalox_light/documents/KL_Brochure_NEW_ver_1.1.pdf

So, my question is why the first data set says service and backwash flow in gpm/ft^2 and the second data set says service and backwash flow in just gpm (although the second chart does provide media volume in both m^3 and ft^3).

I guess I'm asking if there is a nice neat and clean conversion from gpm/ft^2 and gpm/ft^3? And, when measuring my well production should I be stating my flow in gpm/ft^2 or gpm/ft^3? It doesn't seem to make sense to me to measure a volume flow in ft^2, but I'm just a dude who downloaded a datasheet and is asking questions!

I can't wrap my head around the below information I found on Katalox Light.

Background: I have a shallow well that produces ~5.45gpm. I plan to upgrade my treatment system and am looking for media that requires a backwash rate close to what my well can provide. Below is what I found on Katalox....

Source: http://watchwater.com/katalox_light/katalox_light.php

But, I also found the following from the same site:

Source: http://watchwater.com/katalox_light/documents/KL_Brochure_NEW_ver_1.1.pdf

So, my question is why the first data set says service and backwash flow in gpm/ft^2 and the second data set says service and backwash flow in just gpm (although the second chart does provide media volume in both m^3 and ft^3).

I guess I'm asking if there is a nice neat and clean conversion from gpm/ft^2 and gpm/ft^3? And, when measuring my well production should I be stating my flow in gpm/ft^2 or gpm/ft^3? It doesn't seem to make sense to me to measure a volume flow in ft^2, but I'm just a dude who downloaded a datasheet and is asking questions!