obriendigital

New Member

Hello,

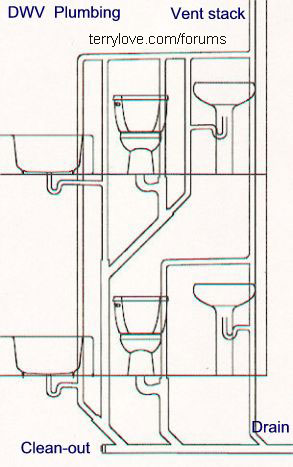

I am trying to add a sink drain and also a washer box. The black lines in the photo show existing infrastructure. I would like to install a sink and washer box. I am assuming I will need to cut into the 3 to 4" section with the cleanout and install some sort of T with a 2" out to the drain for the sink and washer. Where do I put the P trap or traps and also where is it best to vent. I also have a 2" pipe on the other side of the wall that could be accessed overhead for a vent. Could someone please help draw this out for me? Thank you!!!

Tim

I am trying to add a sink drain and also a washer box. The black lines in the photo show existing infrastructure. I would like to install a sink and washer box. I am assuming I will need to cut into the 3 to 4" section with the cleanout and install some sort of T with a 2" out to the drain for the sink and washer. Where do I put the P trap or traps and also where is it best to vent. I also have a 2" pipe on the other side of the wall that could be accessed overhead for a vent. Could someone please help draw this out for me? Thank you!!!

Tim