jmmec

New Member

Hi,

I had someone start a re-build for a custom shower on a 2nd floor (plywood subfloor). The original shower was not built correctly, and it is costing a lot of $$ to redo it (no warranty).

The guy working on the shower is at the shower pan phase, and I've figured out that the pre-slope was not done correctly, and I have concerns about how the shower pan was pieced together. So I want to tear it all out and re-start from scratch. I'm thinking I'll do everything myself.

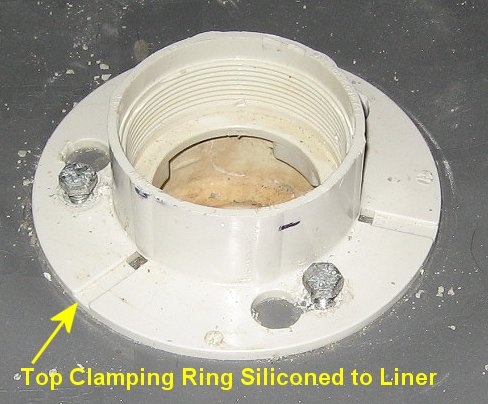

The bad thing is that the guy doing the job siliconed both the top and bottom of the drain assembly to the shower pan (also the weep holes are partially clogged!). So I can't easily remove the top clamping ring since it is glued on pretty tight with silicone.

I have two questions:

Unfortunately, I do not have access to underneath the shower -- it is on a 2nd floor.

By the way, I'm pretty sure the drain pipe is PVC since I see signs of the purple primer, but I'm not sure if the drain assembly is ABS or PVC (I'm sorta dumb in that area), but it is definitely glued to the 2" waste pipe.

Attached are some pictures of what the drain currently looks like with the shower pan, and there is a plywood subfloor under the shower pan liner. The tile guy re-used the bolts from the original drain, and the top of the bolts are almost stripped.

I appreciate your help!

I had someone start a re-build for a custom shower on a 2nd floor (plywood subfloor). The original shower was not built correctly, and it is costing a lot of $$ to redo it (no warranty).

The guy working on the shower is at the shower pan phase, and I've figured out that the pre-slope was not done correctly, and I have concerns about how the shower pan was pieced together. So I want to tear it all out and re-start from scratch. I'm thinking I'll do everything myself.

The bad thing is that the guy doing the job siliconed both the top and bottom of the drain assembly to the shower pan (also the weep holes are partially clogged!). So I can't easily remove the top clamping ring since it is glued on pretty tight with silicone.

I have two questions:

- Any ideas how to remove the top clamping ring without doing damage to the rest of the drain assembly? Looks like he used A LOT of silicone underneath it.

- Is it best to tear out the entire drain assembly and start over? If so, can it be done without tearing out the plywood subfloor? Could a plumber use an inside pipe cutter and replace the drain assembly?

Unfortunately, I do not have access to underneath the shower -- it is on a 2nd floor.

By the way, I'm pretty sure the drain pipe is PVC since I see signs of the purple primer, but I'm not sure if the drain assembly is ABS or PVC (I'm sorta dumb in that area), but it is definitely glued to the 2" waste pipe.

Attached are some pictures of what the drain currently looks like with the shower pan, and there is a plywood subfloor under the shower pan liner. The tile guy re-used the bolts from the original drain, and the top of the bolts are almost stripped.

I appreciate your help!

Last edited by a moderator: