backwaterdogs

New Member

Hello,

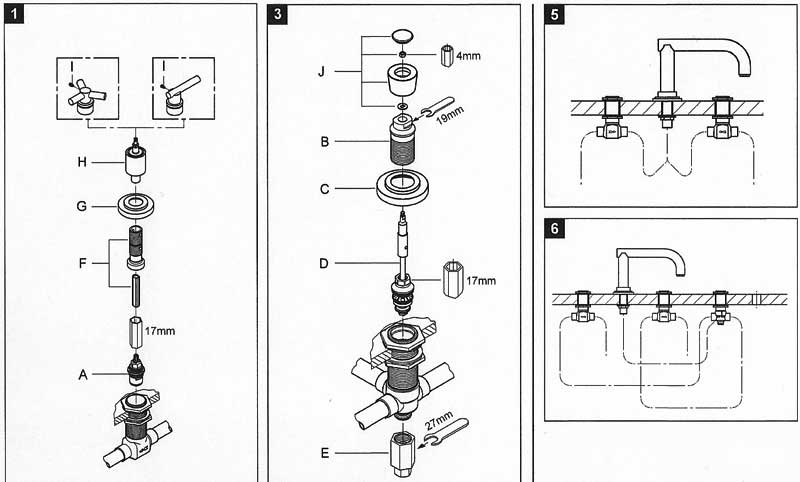

I'm installing a Grohe Atrio roman tub filler faucet. The supply lines I have are 1/2" (but 3/4" not too far back). The inlet to the valves are and spout are all 3/4" and was wondering if the supply should also be 3/4".

The rated flow for the faucet 13.2 gpm and it's filling a big darn tub. I don't want to sacrifice flow, so can get 3/4" supply if need be.

Also and this may answer the above question, but there are two valves, 1 hot 1 cold and you need to plumb from each supply to the valve and the outlet from the valves 'T' into the spout. How would it be best to plumb this? Should I sweat in threaded adapters and use flexible supply hose or sweat copper in between everything? Hose would probably a lot easier for me and not sure if I can safely sweat everything...very close to an acrylic tub! I assumed all the flexible stuff will be 1/2" tho.

I am leaving an access panel and this won't be getting inspected, so PEX is an option for me too.

Thanks for all your help!

I'm installing a Grohe Atrio roman tub filler faucet. The supply lines I have are 1/2" (but 3/4" not too far back). The inlet to the valves are and spout are all 3/4" and was wondering if the supply should also be 3/4".

The rated flow for the faucet 13.2 gpm and it's filling a big darn tub. I don't want to sacrifice flow, so can get 3/4" supply if need be.

Also and this may answer the above question, but there are two valves, 1 hot 1 cold and you need to plumb from each supply to the valve and the outlet from the valves 'T' into the spout. How would it be best to plumb this? Should I sweat in threaded adapters and use flexible supply hose or sweat copper in between everything? Hose would probably a lot easier for me and not sure if I can safely sweat everything...very close to an acrylic tub! I assumed all the flexible stuff will be 1/2" tho.

I am leaving an access panel and this won't be getting inspected, so PEX is an option for me too.

Thanks for all your help!

Last edited by a moderator: