Rao

New Member

Friends,

Thanks in advance for any help on this. This work needs to be code and sensible as I am selling this unit and it will inspected. Questions essentially comes down to if two 90 degree in a hand washing sink are allowed.

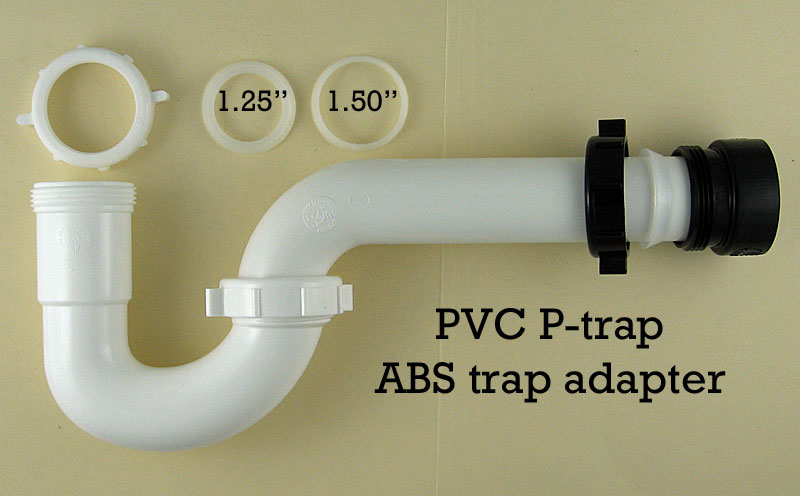

I have remodeled a small half bath in my place. The plumbing seemed fine for the vanity I had picked so other than installing new 1/4 stops on h/c and toilet supply I left as is when I rehung walls. So my drain remains a 1 12 pvc with p trap on a swing-able lower part of the p trap.

I ran into the problem that the old 22" vanity there when I bought the place was not in code by a long shot in terms of proximity to the toilet (it was 11 inches from center-line, not 15), meaning the new vanity I had picked as a replacement was a no-go.

with a limit of 18 inches wide, my wife found and bought a a nice vanity set with granite top and vessel sink at a good price online. the drain hole placement for this vessel is well foreword n the vanity and it has a frosted glass door. The glass door incline me to use chrome, and the placement of the drain incline me to use chromed instead of pcv.

The sink came with a popup drain to a brass thread piece, to a chrome piece femail threaded on upper end and an extension like piece about 12 inches long with a flange on one end. it also came with what looks like a a custom p trap. Using the included pe trap, which gives me a short drop to 90 degrees back , which is what I want would look dumb with two p-traps for a single sink.

Q 1) I would prefer to use a 90 degree slip joint elbow about 3" below drain to create a horizontal straight back toward wall, and then a second 90 slip joint elbow to create vertical down to the p trap which I can turn to be flat against the wall. This will give me optimum space inside this small vanity and will also allow use of the included shelf, and have only chrome visible through the frosted glass. I see Ikea setups with even less of a drop from the sink to 90 degrees horizontal. Is this allowed by code? Does it look "hacky?" I seem to double 90 degree offset on pcv on ADA compliant lav sinks (for wheelchair access) but I have not seen one in chrome

My other alternative is to use a 1 1/4 chrome "double 45 degree offset". this will necessitate me cutting into the shelf of the vanity so I would prefer not.

Q 2) this sink has a popup and no secondary drain. Is there a universal or easy way to disable pop up stoppers? (the drain is no name so I cant check a site). I assume disable pop up would be ok by code. I don't want to remove the actually stopper center piece since I would just have a hole. I just want to lock it in the elevated position.

Thanks!

Thanks in advance for any help on this. This work needs to be code and sensible as I am selling this unit and it will inspected. Questions essentially comes down to if two 90 degree in a hand washing sink are allowed.

I have remodeled a small half bath in my place. The plumbing seemed fine for the vanity I had picked so other than installing new 1/4 stops on h/c and toilet supply I left as is when I rehung walls. So my drain remains a 1 12 pvc with p trap on a swing-able lower part of the p trap.

I ran into the problem that the old 22" vanity there when I bought the place was not in code by a long shot in terms of proximity to the toilet (it was 11 inches from center-line, not 15), meaning the new vanity I had picked as a replacement was a no-go.

with a limit of 18 inches wide, my wife found and bought a a nice vanity set with granite top and vessel sink at a good price online. the drain hole placement for this vessel is well foreword n the vanity and it has a frosted glass door. The glass door incline me to use chrome, and the placement of the drain incline me to use chromed instead of pcv.

The sink came with a popup drain to a brass thread piece, to a chrome piece femail threaded on upper end and an extension like piece about 12 inches long with a flange on one end. it also came with what looks like a a custom p trap. Using the included pe trap, which gives me a short drop to 90 degrees back , which is what I want would look dumb with two p-traps for a single sink.

Q 1) I would prefer to use a 90 degree slip joint elbow about 3" below drain to create a horizontal straight back toward wall, and then a second 90 slip joint elbow to create vertical down to the p trap which I can turn to be flat against the wall. This will give me optimum space inside this small vanity and will also allow use of the included shelf, and have only chrome visible through the frosted glass. I see Ikea setups with even less of a drop from the sink to 90 degrees horizontal. Is this allowed by code? Does it look "hacky?" I seem to double 90 degree offset on pcv on ADA compliant lav sinks (for wheelchair access) but I have not seen one in chrome

My other alternative is to use a 1 1/4 chrome "double 45 degree offset". this will necessitate me cutting into the shelf of the vanity so I would prefer not.

Q 2) this sink has a popup and no secondary drain. Is there a universal or easy way to disable pop up stoppers? (the drain is no name so I cant check a site). I assume disable pop up would be ok by code. I don't want to remove the actually stopper center piece since I would just have a hole. I just want to lock it in the elevated position.

Thanks!

Last edited by a moderator:

![bath2].jpg bath2].jpg](https://terrylove.com/forums/data/attachments/20/20399-03f3377a06a8e8d86fdbd946199be010.jpg)