Baumgrenze

Member

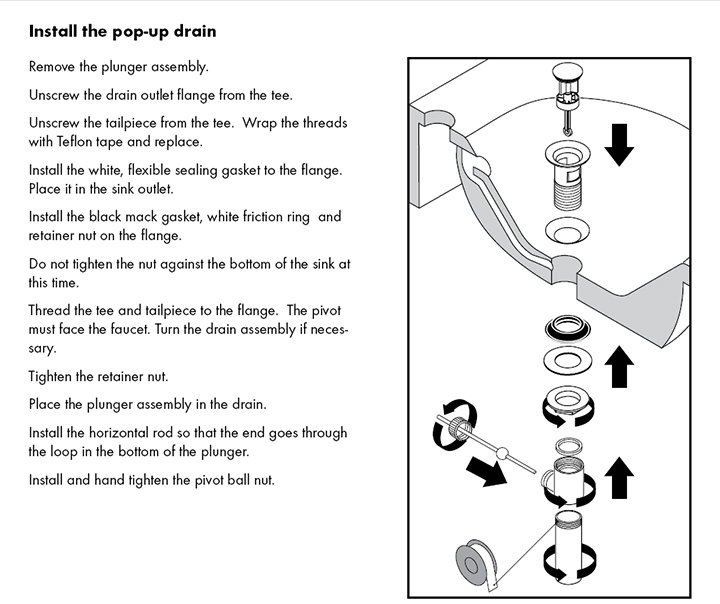

I want to install a 885209820 HansGrohe popup assembly like the one illustrated in the attached image.

My sink is a Ronbow RON-CB4002 ceramic above counter vessel sink with overflow mounted on Caesarstone over two layers of 3/4" Baltic birch plywood. This puts the horizontal rod too close to the underside of the overall counter for straightforward fitting and operation.

The drain outlet flange appears to be a straight pipe thread, 1.285" across the threads and 13 threads/inch (best match to a thread gauge in my tap&die set. This thre

Since the drain outlet flange (1-1/2 ") threads into the horizontal lever tee as a separate piece, it seems to me that it might be feasible to insert a brass extension.

I have actual photos of the fitting, but they are 5x too big to upload. I can try resizing if someone thinks they would be preferable.

My sink is a Ronbow RON-CB4002 ceramic above counter vessel sink with overflow mounted on Caesarstone over two layers of 3/4" Baltic birch plywood. This puts the horizontal rod too close to the underside of the overall counter for straightforward fitting and operation.

The drain outlet flange appears to be a straight pipe thread, 1.285" across the threads and 13 threads/inch (best match to a thread gauge in my tap&die set. This thre

Since the drain outlet flange (1-1/2 ") threads into the horizontal lever tee as a separate piece, it seems to me that it might be feasible to insert a brass extension.

I have actual photos of the fitting, but they are 5x too big to upload. I can try resizing if someone thinks they would be preferable.

Attachments

Last edited by a moderator: