I made a dry run (maybe I should say "wet run"  ) of the water test on my complete DWV redo for my old house renovation project. I thought it wise to check it out beforehand and not try it the first time with the inspector there. It went pretty well except for a couple of problems.

) of the water test on my complete DWV redo for my old house renovation project. I thought it wise to check it out beforehand and not try it the first time with the inspector there. It went pretty well except for a couple of problems.

1. There are 2, 4" PVC cleanout plugs and one 2" cleanout plug in the basement that I could not get to completely stop "weeping" during the test.

They started weeping pretty good at first. I was able to get it to slow down (especially on the 2" plug), but not stop completely, by tightening the plugs as tight as I could during the test. The 4" COs are especially hard to turn.

There is about 30' of water head in 3" vertical pipe (the 4" pipe is just the horizontal building drain) above the cleanouts. There are many other cleanouts in the system, but none of them leaked at all (I'm guessing the lesser head pressure on the cleanouts at a higher elevation in the system have an advantage - although one that did not leak is only a couple feet higher, plus once these lower COs started leaking I sprinted around to tighten the others). They were all sealed with Rector Seal applied to both the male and female threads before tightening. Any ideas how to stop the weeping. I'm sure I'll fail the real inspection if the COs are weeping.

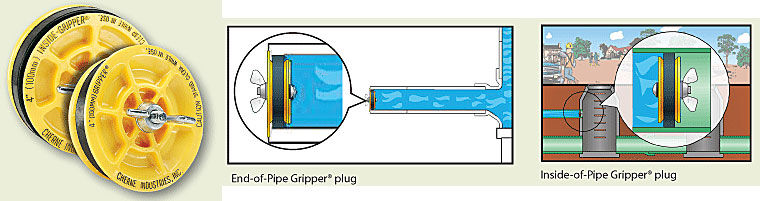

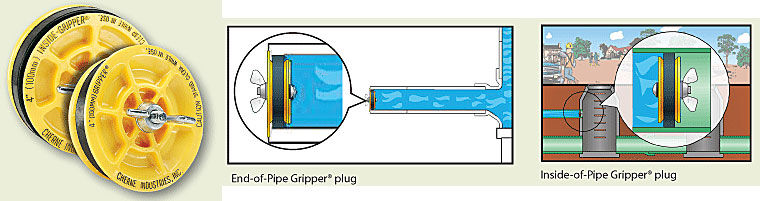

2. (This one is more for entertainment value ) I setup the DWV so that the new can be isolated from the old by removing a 4" Fernco where they meet and capping the new system with a 4" cap. I then use a pneumatic plug in the CO wye just outside the building and fill away with the hose. The 4" cap I used was a rubber cap w/a hose clamp (like the Fernco). All was going well until I heard a loud "POP" in the basement. I ran inside and downstairs to find water pouring out where this cap USED to be. The cap was from Lowes and is American Valve brand I think (ironically made in China) and I'm guessing it is not rated to hold 30' of water head. Next time I'll use something like a Cherne mechanical plug that is rated to hold 30-35' of water. Fortunately no damage done by the water or the cap blowing out. Just a mess to cleanup. I'll bet that cap flying out would have been something to see. It was pretty loud outside even through the basement wall and scared my wife pretty good inside. Lesson learned.

) I setup the DWV so that the new can be isolated from the old by removing a 4" Fernco where they meet and capping the new system with a 4" cap. I then use a pneumatic plug in the CO wye just outside the building and fill away with the hose. The 4" cap I used was a rubber cap w/a hose clamp (like the Fernco). All was going well until I heard a loud "POP" in the basement. I ran inside and downstairs to find water pouring out where this cap USED to be. The cap was from Lowes and is American Valve brand I think (ironically made in China) and I'm guessing it is not rated to hold 30' of water head. Next time I'll use something like a Cherne mechanical plug that is rated to hold 30-35' of water. Fortunately no damage done by the water or the cap blowing out. Just a mess to cleanup. I'll bet that cap flying out would have been something to see. It was pretty loud outside even through the basement wall and scared my wife pretty good inside. Lesson learned.

All joking aside, I guess that is a good reminder to be careful with test plugs as 30' of water head in 3" pipe creates about 100 lbs of force on the plug (if I did the math right). That could definitely cause some injury and maybe even get somebody killed if you got hit in the head at close range.

Thanks,

Joel

http://www.cherneind.com/

1. There are 2, 4" PVC cleanout plugs and one 2" cleanout plug in the basement that I could not get to completely stop "weeping" during the test.

They started weeping pretty good at first. I was able to get it to slow down (especially on the 2" plug), but not stop completely, by tightening the plugs as tight as I could during the test. The 4" COs are especially hard to turn.

There is about 30' of water head in 3" vertical pipe (the 4" pipe is just the horizontal building drain) above the cleanouts. There are many other cleanouts in the system, but none of them leaked at all (I'm guessing the lesser head pressure on the cleanouts at a higher elevation in the system have an advantage - although one that did not leak is only a couple feet higher, plus once these lower COs started leaking I sprinted around to tighten the others). They were all sealed with Rector Seal applied to both the male and female threads before tightening. Any ideas how to stop the weeping. I'm sure I'll fail the real inspection if the COs are weeping.

2. (This one is more for entertainment value

All joking aside, I guess that is a good reminder to be careful with test plugs as 30' of water head in 3" pipe creates about 100 lbs of force on the plug (if I did the math right). That could definitely cause some injury and maybe even get somebody killed if you got hit in the head at close range.

Thanks,

Joel

http://www.cherneind.com/

Last edited by a moderator: