Hello! I've been looking for a place to ask opinions on an idea. This forum come recommended.

I live in SC. We have three hot humid seasons typically, the winters are generally mild with 1-2 light snow falls each year but the temp usually drops to low to mid 20's in winter. What else? I'm on well water pumped by a 3/4Hp pump through a water softener. All the pipe is PVC / CPVC except the bladder tank, switch and gauge which are all on about a 3ft glavanized section. Not sure if you'll care about all that.

I am new to this, but have wanted to try building a solar water heater for some time. I did quite a lot of research, some drawings and a schematic for what you might call a flat panel / evacuated tube combination design.

The (my) idea started with a video from a young man in Brazil? that built his own flat panel:

Which led to a DIY evacuated tube (cheap - proof of concept) video:

I'd like to use 1/2" copper pipe in 4ft section, painted black, inserted in a glass evacuated tube. All DIY stuff. The glass will be cut and cleaned 4ft T8 bulbs which have gone bad and been replaced. I plan to use a resin compound to seal each end with about 2" of the copper out the top and bottom. Assembly will be the typical parallel tube flat panel thermosiphon design. the bottom plug on each tube will have a 1/8" pneumatic line cast into the plug, all leading to a manifold to draw vacuum and maintain vacuum if needed.

I'd like opinions please. The thought is the vacuum is an excellent insulator (obviously) which will contain the heat and boost efficiency a LOT?. The other option is a typical flat panel with glass face and evacuate the air in the box, but I don't think that will work very well.

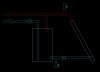

From there, I'd like to put an electric shorty 48gal water heater in the attic over a wall with power to supplement the solar. The collector will be roof mounted about the same level as the electric water heater, which SHOULD eliminate the need for a pump. The plan is, the collector heats the water all day in the tank, then we use the water in the evening.

The prototype will likely be 2-3 rows of CPVC inside evacuated glass tube heating a small sealed 1gal tank. If all goes well, I'll boil water and melt CPVC then build a small 2x2ft panel for the hot tub, work the bugs out, then one for the house.

then build a small 2x2ft panel for the hot tub, work the bugs out, then one for the house.

I live in SC. We have three hot humid seasons typically, the winters are generally mild with 1-2 light snow falls each year but the temp usually drops to low to mid 20's in winter. What else? I'm on well water pumped by a 3/4Hp pump through a water softener. All the pipe is PVC / CPVC except the bladder tank, switch and gauge which are all on about a 3ft glavanized section. Not sure if you'll care about all that.

I am new to this, but have wanted to try building a solar water heater for some time. I did quite a lot of research, some drawings and a schematic for what you might call a flat panel / evacuated tube combination design.

The (my) idea started with a video from a young man in Brazil? that built his own flat panel:

Which led to a DIY evacuated tube (cheap - proof of concept) video:

I'd like to use 1/2" copper pipe in 4ft section, painted black, inserted in a glass evacuated tube. All DIY stuff. The glass will be cut and cleaned 4ft T8 bulbs which have gone bad and been replaced. I plan to use a resin compound to seal each end with about 2" of the copper out the top and bottom. Assembly will be the typical parallel tube flat panel thermosiphon design. the bottom plug on each tube will have a 1/8" pneumatic line cast into the plug, all leading to a manifold to draw vacuum and maintain vacuum if needed.

I'd like opinions please. The thought is the vacuum is an excellent insulator (obviously) which will contain the heat and boost efficiency a LOT?. The other option is a typical flat panel with glass face and evacuate the air in the box, but I don't think that will work very well.

From there, I'd like to put an electric shorty 48gal water heater in the attic over a wall with power to supplement the solar. The collector will be roof mounted about the same level as the electric water heater, which SHOULD eliminate the need for a pump. The plan is, the collector heats the water all day in the tank, then we use the water in the evening.

The prototype will likely be 2-3 rows of CPVC inside evacuated glass tube heating a small sealed 1gal tank. If all goes well, I'll boil water and melt CPVC

Last edited by a moderator: