Robert Nollkamper

New Member

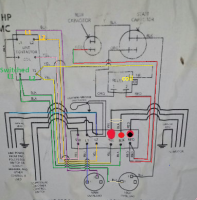

Hi, I've been a lurker for some time, but this is a first time post. I moved into this house a little over a year ago, and the water smelled like sulfur. I decided to make some upgrades to the well, so I put in a CSV1W, Stenner Chlorinator, softener, carbon filter; everything was fine until My Stenner started making a bunch of racket about 2 months ago, and now my Overload switch has reset a couple times on my well. I tested the run capacitor and it isn't happy. I'm wondering if the way I connected the stenner pump could have caused premature failure to both it and the capacitor. Could someone tell me if there is a better way to connect it?