tpcolson

New Member

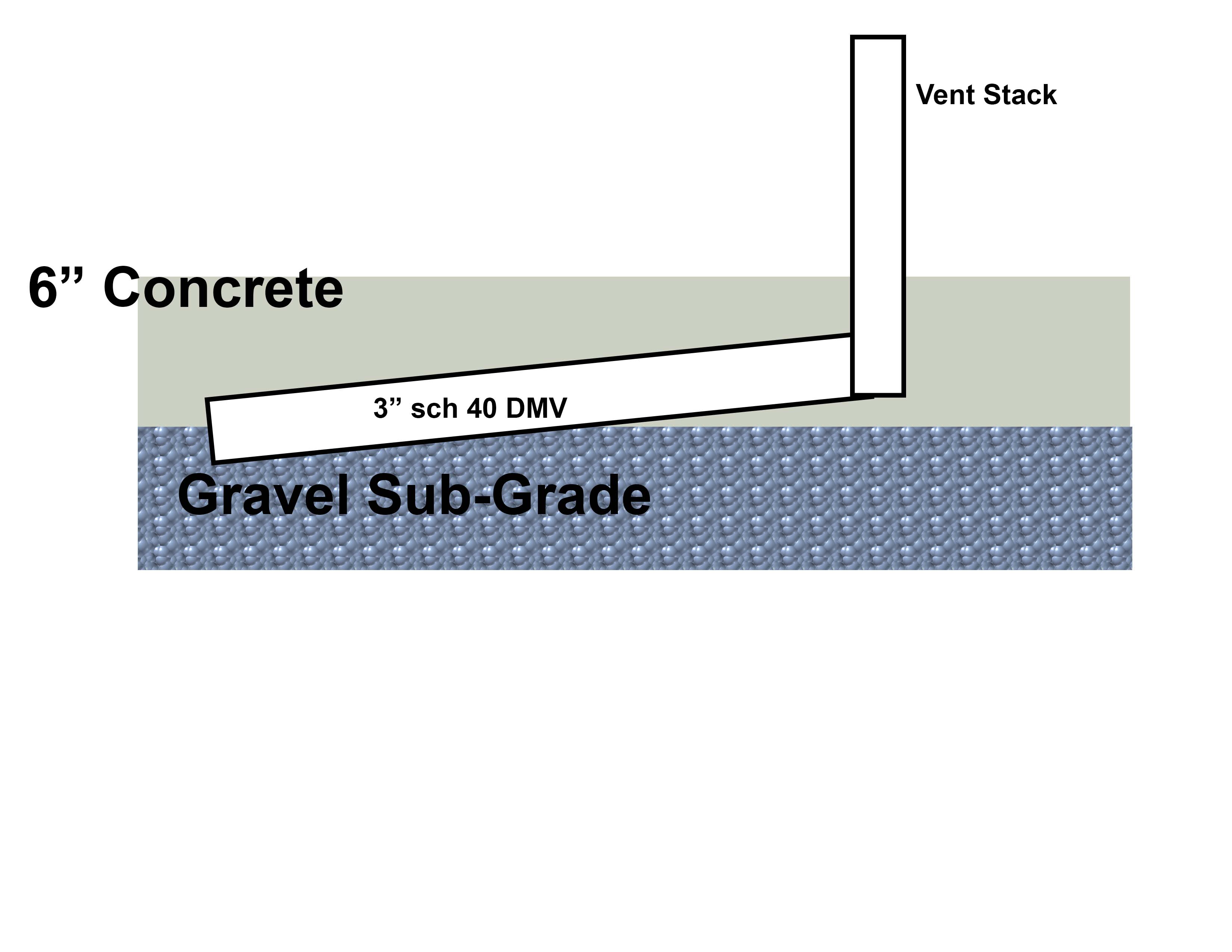

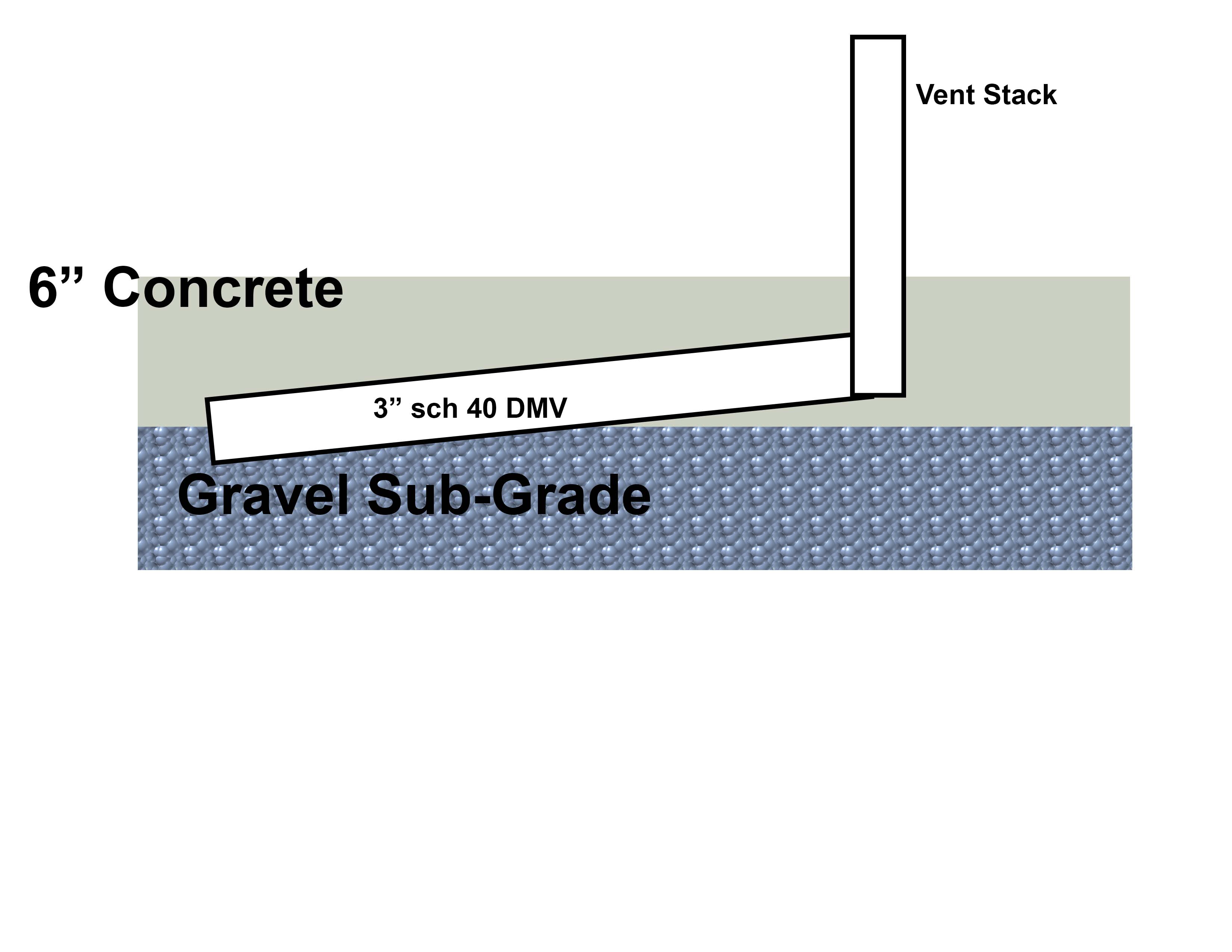

Have an unfortunate "this is the only way this is going to work" situation with a DMV repair, resulting in the repair portion of the drain pipe, having to run 4 feet horizontally (yes, at the correct slope of 1/4"/ft) before turning up into the main vent stack...mostly above the gravel sub-grade and tapering into being completely within the 6" horizontal space where the concrete slab will be repoured. Question is, can 3" sch. 40 PVC pipe be directly embedded in concrete? Not covered by, or under, but directly embedded (concrete will fully encase 4ft of the pipe). Wondering if the heat of curing will warp/crush the pipe? I know horizontal stub-outs come through a concrete slab all of the time with no issue, but not seeing a lot of examples of horizontal embedding. I'm sure there are other ways to do this without the last-ditch option of embedding PVC horizontally in concrete, but those involve a 5-figure $$ removal of the entire basement slab and replacement of every single pipe.....just to get that 4' run of PVC encased completely in the gravel sub grade. The attached photo is a very poor rendition of what's going on here, not to scale, best a non-computer person could do!