There seems to be so much information out there on this, but I need a sensible approach for a functional system that may not be able to be "by the numbers" because of access, complexity, cost or other factors.

Hopefully I can come close. The particulars are as follows:

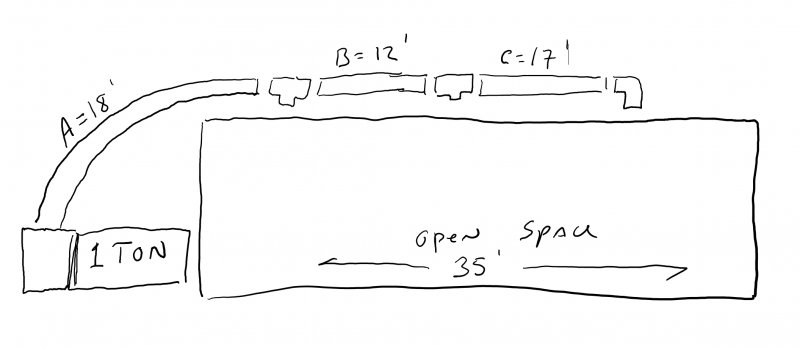

* System - 1 ton / 400-500 CFM 3 speed adjustment air handler.

* All ductwork has to be flex

* Planning on a 10" return on the left wall - next to unit. (length will be single run of less than 8').

Looking at the drawing, what size flex should "A", "B", and "C" be (ideally) and what would be the best way to transition from the flex to ceiling registers at these points? I'm having to cut into an existing ceiling from below to do this - I have 18" of height in the joist spaces, with 18" width. There is some fiberglass insulation in there as well, but can be mashed a bit.

I'd like to have fairly quiet supplies, but it isn't a recording studio or anything - just don't want the system running to draw much attention to that fact.

Thanks for any insight!

Hopefully I can come close. The particulars are as follows:

* System - 1 ton / 400-500 CFM 3 speed adjustment air handler.

* All ductwork has to be flex

* Planning on a 10" return on the left wall - next to unit. (length will be single run of less than 8').

Looking at the drawing, what size flex should "A", "B", and "C" be (ideally) and what would be the best way to transition from the flex to ceiling registers at these points? I'm having to cut into an existing ceiling from below to do this - I have 18" of height in the joist spaces, with 18" width. There is some fiberglass insulation in there as well, but can be mashed a bit.

I'd like to have fairly quiet supplies, but it isn't a recording studio or anything - just don't want the system running to draw much attention to that fact.

Thanks for any insight!