carpenter2006

New Member

- Messages

- 1

- Reaction score

- 0

- Points

- 0

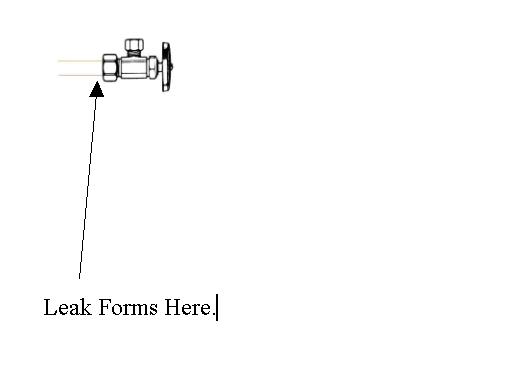

I just installed a new pedestal sink. I connected a 5/8" inlet compression angle valve to my incoming copper supply line. I used thread sealant on the male threads and screwed the nut in. When I turn on the house water I get a very tiny leak (1 drop every 2 minutes) on the back edge of the compression nut. See attached document picture.

How can I correct this? Do I need to tighten nut further? Did I over tighten? Is there something I can apply to the back of the nut and copper pipe that can seal this leak?

Thank you. Any help would appreciated!!!

How can I correct this? Do I need to tighten nut further? Did I over tighten? Is there something I can apply to the back of the nut and copper pipe that can seal this leak?

Thank you. Any help would appreciated!!!

Last edited by a moderator: