psuce

New Member

Hello all and thanks in advance for any and all help and information. I currently have an old farmhouse with a Thermo-Dynamics boiler. It currently has two zones. One is for the primary part of the house which is heated with nine (9) radiators. The second zone is solely heating the kitchen via a kick-space heater. I had it installed about 20 years ago by a local reputable dealer. I want to break up the main part of the house into two zones (5 & 4 radiators). The dealer wants a small fortune to add an additional zone so I thought I would see what is involved and what my options may be. I have a friend that is a licensed plumber who can more than handle the installation. I am just not sure of his expertise with the design/details of adding a zone. There will be no additional capacity or demand on the system. Just trying to split main part of the house for convenience and control.

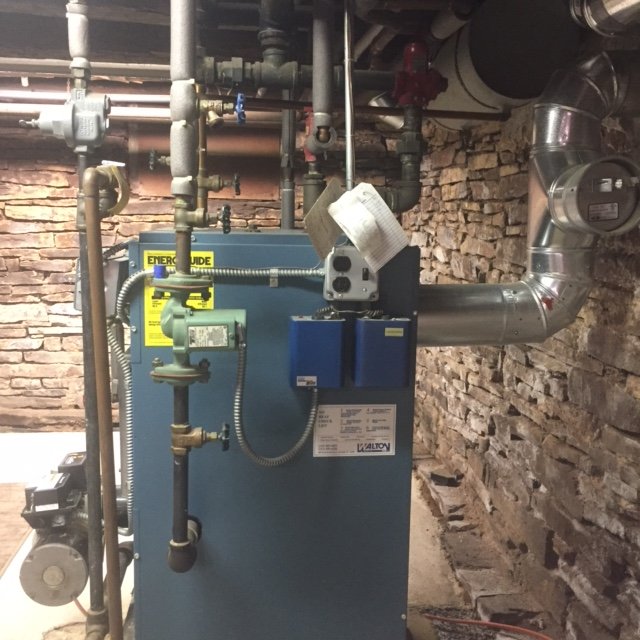

As can be seen in the attached photo(s), the supply for both zones comes out of the top of the boiler. The 3/4" supply passes the flow valve and goes to the kitchen which then returns to the right side of the boiler. The 1-1/4" supply (which I want to split) passes the flow valve and then splits to the front and back of the house which then return and merge before going to the circulator. I was wondering if it is as simple as adding another 1-1/4" tee and flow valve coming out of the boiler and plumbing one side of the supply into this valve while leaving the other supply side connected as is. I would then "mirror" the existing setup on the return (left) side adding another circulator for the new zone to the right side using a 1-1/4" tee where existing elbow is connecting the 3/4" return from the kitchen.

As can be seen, there is a bypass on the return side from below the circulator back to the supply side which it is my understanding helps keep the radiators from overheating. I assume I would have to include this in my "mirroring" of the existing setup when installing the new setup.

As can be seen in the attached photo(s), the supply for both zones comes out of the top of the boiler. The 3/4" supply passes the flow valve and goes to the kitchen which then returns to the right side of the boiler. The 1-1/4" supply (which I want to split) passes the flow valve and then splits to the front and back of the house which then return and merge before going to the circulator. I was wondering if it is as simple as adding another 1-1/4" tee and flow valve coming out of the boiler and plumbing one side of the supply into this valve while leaving the other supply side connected as is. I would then "mirror" the existing setup on the return (left) side adding another circulator for the new zone to the right side using a 1-1/4" tee where existing elbow is connecting the 3/4" return from the kitchen.

As can be seen, there is a bypass on the return side from below the circulator back to the supply side which it is my understanding helps keep the radiators from overheating. I assume I would have to include this in my "mirroring" of the existing setup when installing the new setup.