Thanks for all the GREAT Advice from my previous post !!!

What I have is a well bored to 180' with a static water level at 50 feet with 100+ gpm, PVC casing was used to bedrock.

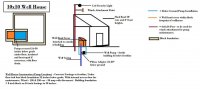

I am planning on installing a 3/4 hp pump to 125 feet and coming out of the wellhead to a small 8x8 well house structure, then installing the pressure tank in an insulated space 2 feet below grade recessed under the floor of the well house. From the well house to the future house build site is about 100ft. I decided on a 3/4 hp pump due to 3 reasons, 1) Possible future need for water irrigation for tree nursery, 2) Wanting to use an upgraded shower in the home. 3) It seems 3/4 was the MOST recommended without overkill.

I need some input on materials to use....as it seems I am getting estimates from companies using a lot less quality materials...Simply, I want to install the pump system, locate it in and below grade in a structure and provide unencumbered access to avoid burying a pressure tank, which is another issue I am not comfortable with.

While a lot of you guys here recommend using, (as I do and prefer) a higher schedule 120 or 160 psi 1.25 PVC as the drop pipe material. Two pump installers have estimated the job at 3000.00 using the thin walled 1" black rolled pipe, and I am not convinced that the thinned walled black pipe is adequate for the job over the long term. One estimate was for a Grandfos 3/4 pump which is good, the other was for a Jacuzzi pump, not even made anymore from what I am told.

The well structure is about 8x8 with access in the floor to the pump system and the structure will be wired with 120 and 230 circuits with shutoffs. I could use a Pitless install or just protect the well head from freezing and plumb directly into the bottom of the well house.

Correction of the attached drawing: The well tank is going to be located inside,,,the pump of course in the well.

What are your thoughts?

Thanks

What I have is a well bored to 180' with a static water level at 50 feet with 100+ gpm, PVC casing was used to bedrock.

I am planning on installing a 3/4 hp pump to 125 feet and coming out of the wellhead to a small 8x8 well house structure, then installing the pressure tank in an insulated space 2 feet below grade recessed under the floor of the well house. From the well house to the future house build site is about 100ft. I decided on a 3/4 hp pump due to 3 reasons, 1) Possible future need for water irrigation for tree nursery, 2) Wanting to use an upgraded shower in the home. 3) It seems 3/4 was the MOST recommended without overkill.

I need some input on materials to use....as it seems I am getting estimates from companies using a lot less quality materials...Simply, I want to install the pump system, locate it in and below grade in a structure and provide unencumbered access to avoid burying a pressure tank, which is another issue I am not comfortable with.

While a lot of you guys here recommend using, (as I do and prefer) a higher schedule 120 or 160 psi 1.25 PVC as the drop pipe material. Two pump installers have estimated the job at 3000.00 using the thin walled 1" black rolled pipe, and I am not convinced that the thinned walled black pipe is adequate for the job over the long term. One estimate was for a Grandfos 3/4 pump which is good, the other was for a Jacuzzi pump, not even made anymore from what I am told.

The well structure is about 8x8 with access in the floor to the pump system and the structure will be wired with 120 and 230 circuits with shutoffs. I could use a Pitless install or just protect the well head from freezing and plumb directly into the bottom of the well house.

Correction of the attached drawing: The well tank is going to be located inside,,,the pump of course in the well.

What are your thoughts?

Thanks

Attachments

Last edited: