I have attached a pdf of the floorplan and pictures in its current state. The house is in Arizona and it's a conversion of an old addition into a larger new space with additional plumbing fixtures.

1. Do all the fittings look correct?

2. Should the toilet be fitted further downstream of the Lav (or upstream of the others)?

3. Do the vent positions look correct?

4. Because there are preexisting roof penetrations for 2" and 1 1/2" vents, can I tie them together on the same vent circuit? or should I vent the CW and LT independently by using the 1 1/2" penetration and then use the 2" penetration for the bath group?

5. What should I install/use for testing during inspection? Should I add a separate tee where the new and old plumbing meet in order to insert a balloon/bladder?

6. Does air pressure testing happen at this stage as well as the water test?

I'm sure I will have more questions, but any advice is appreciated.

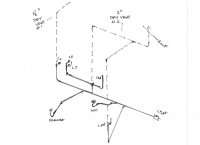

- Existing 3" drain line leads to the house main, then to the city main. A cleanout furthest downstream of the addition space is visible in at least one photo. Just upstream of the cleanout is the beginning of the new DWV plumbing.

- Above (approximately) the new 3" drain line will be the wet wall servicing the bath group (Shower, Lav and WC) on one side and the laundry group (CW standpipe and LT) on the other side.

- The current design lays out the following, from upstream to downstream -

2" vent with cleanout -->

Shower -->

CW and LT on a back-to-back fitting with 2" vent reducing to 1 1/2" vent above the ceiling -->

Toilet -->

Lav -->

Existing cleanout outside

Shower -->

CW and LT on a back-to-back fitting with 2" vent reducing to 1 1/2" vent above the ceiling -->

Toilet -->

Lav -->

Existing cleanout outside

2. Should the toilet be fitted further downstream of the Lav (or upstream of the others)?

3. Do the vent positions look correct?

4. Because there are preexisting roof penetrations for 2" and 1 1/2" vents, can I tie them together on the same vent circuit? or should I vent the CW and LT independently by using the 1 1/2" penetration and then use the 2" penetration for the bath group?

5. What should I install/use for testing during inspection? Should I add a separate tee where the new and old plumbing meet in order to insert a balloon/bladder?

6. Does air pressure testing happen at this stage as well as the water test?

I'm sure I will have more questions, but any advice is appreciated.

Attachments

Last edited: