Digital Geek

Member

The pump doesn't "slow down" when restricted with a valve, it actually speeds up a little. As TW said, it is moving less water so there is less work. The amps actually drop, even though the motor speeds up. Do the same test with a hair blower or a vacuum cleaner. When you hold your hand over the discharge, you can hear the motor speed up. If you use an amp meter, you will see that the amps decrease.

The pump you have was not designed to do this very well, but the amps still drop a little. Some pumps are much better at dropping amps than others. It was probably an accident by design, but still some will drop 50% or more.

Look at the horsepower (HP) curve on the bottom of the pump curves I posted. These are 3450 RPM curves, not variable speed curves. Yet notice that the HP drops from .71HP at 17 GPM to .38HP at 4 GPM. My 2HP Grundfos drops from 12 amps when using 25 GPM to 4 amps when running a 3 GPM drip system. That is why I showed you those curves. That is a natural characteristic of a centrifugal impeller pump, you don't have to vary the speed to see a decrease in energy use. You just have to pick a pump that naturally has a good drop in HP if you want it efficient at low and high flow rates.

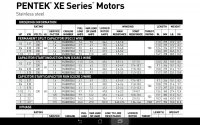

thanks again. I will move forward with this pump 16S05-5 which motor though?