You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Triangle Tube or Cast Iron?

- Thread starter Estrada

- Start date

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)

Well, that was weird. The guy recommended by the regional rep did a heat loss analysis, then was late with a quote, in which he didn't include the analysis, recommended the 110, and quoted 35% higher than the other factory-trained bidder. I've asked him for the analysis. Presumably he'll send it to me at some point.

Last edited:

Sponsor

Paid Advertisement

I was wrong. Is this typical?

"I wish I could send you a copy but it is against our policy. History has shown us that it's not helpful. I will be happy to share the details and results of my load calculation after you've committed to working with us, and before we order product."

"I wish I could send you a copy but it is against our policy. History has shown us that it's not helpful. I will be happy to share the details and results of my load calculation after you've committed to working with us, and before we order product."

Did you pay him for the calculation?I was wrong. Is this typical?

"I wish I could send you a copy but it is against our policy. History has shown us that it's not helpful. I will be happy to share the details and results of my load calculation after you've committed to working with us, and before we order product."

How long did he spend measuring up stuff for the heat load analysis? And was it based on the "before upgrades" picture, or with the planned insulation upgrades inlcuded?

Why don't YOU measure up stuff, and run an I=B=R spreadsheet?

Or how about running a fuel-use against heating degree-day calculation, using the beastie-boiler as the measuring instrument?

Why don't YOU measure up stuff, and run an I=B=R spreadsheet?

Or how about running a fuel-use against heating degree-day calculation, using the beastie-boiler as the measuring instrument?

I'd be happy to do it, but have no idea what insulation numbers to use--this is not, to understate things by a lot, my area of expertise.

He took at least an hour--I was with him, and he measured everything. He said he would use the planned upgrade numbers.

As for using fuel-use, I still don't have a bill from the gas company, and don't have access to previous bills.

He took at least an hour--I was with him, and he measured everything. He said he would use the planned upgrade numbers.

As for using fuel-use, I still don't have a bill from the gas company, and don't have access to previous bills.

On a 50 year old 2x4 framed house with full-depth batts will be no worse than U0.10 for the walls, no matter what batt type or siding & interior finish you use. With R11 fiberglass or rock wool and wooden siding over plywood sheathing it's no worse than U0.083. If you have at least 5.5" of fluff in the attic the U-factor for the ceiling is no worse than U0.06. Use this for guidance.

Then it's ...

square feet x U-factor x temperature difference= BTU/hr

...for each surface type (ceiling, window, wall, door, etc.)

For the foundation insulation, assume U=1/R if it's just continuous foam, and only count the above-grade portion. If the planned basement insulation is continuous R4-R6 foam trapped to the foundation with a 2x4 fiber-insulated studwall it'll be no worse than U0.065.

Find the nearest city to come up with a 99% outside design temp, use 68F for the interior design temp. For Chicago that's a difference of 68F (not like the conservative 75F I used in my straw-man example.)

The big error bars would then be how much fudge-factor to add for air infiltration, and how much to subtract for resident mammals and 24/7 plug loads like refrigerators, cable boxes, DVRs, etc. But even those can be estimated if need be.

Then it's ...

square feet x U-factor x temperature difference= BTU/hr

...for each surface type (ceiling, window, wall, door, etc.)

For the foundation insulation, assume U=1/R if it's just continuous foam, and only count the above-grade portion. If the planned basement insulation is continuous R4-R6 foam trapped to the foundation with a 2x4 fiber-insulated studwall it'll be no worse than U0.065.

Find the nearest city to come up with a 99% outside design temp, use 68F for the interior design temp. For Chicago that's a difference of 68F (not like the conservative 75F I used in my straw-man example.)

The big error bars would then be how much fudge-factor to add for air infiltration, and how much to subtract for resident mammals and 24/7 plug loads like refrigerators, cable boxes, DVRs, etc. But even those can be estimated if need be.

I went back to the original quote, and expressed my concerns about size. Reply:

"You might be able to just heat your home with the 60 to 68 degrees but you will not have any reserve power for setback or a temporary loss of heat.

The IBR net output of a Triangle tube 60 is 47,000 BTU so 60,000 BTU is the input rating and 47,000 BTU is the net rating minus pipe losses.

The 110 will not short cycle and if it did we have programming options to prevent that."

He says he'll do the 60 if I insist, but won't guarantee sufficient heat. I'm on the verge of capitulation.

"You might be able to just heat your home with the 60 to 68 degrees but you will not have any reserve power for setback or a temporary loss of heat.

The IBR net output of a Triangle tube 60 is 47,000 BTU so 60,000 BTU is the input rating and 47,000 BTU is the net rating minus pipe losses.

The 110 will not short cycle and if it did we have programming options to prevent that."

He says he'll do the 60 if I insist, but won't guarantee sufficient heat. I'm on the verge of capitulation.

Again, the IBR output is irrelevant, since the boiler is being installed inside of conditioned space, not out in the garage on the other side of the insulation. The DOE output is the only relevant number.

The pipe losses are still all inside the house- they're not lost, they're just in the basement, warming up the underside of your first floor. The majority of those losses are still accruing to the heat load even before you insulate the foundation. After you insulate the basement the number of pipe loss BTUs that actually escaped the basement will have dropped by an order of magnitude or so.

With a mod-con you don't really want do use deep setbacks, since that would require higher water temps (= lower efficiency). When you dial in the outdoor reset curve to where the thermostats are (almost) never satisfied but it never loses ground, you will use less fuel than you might have saved with any overnight setback scheme due to the higher efficiency. (IIRC BadgerBoilerMN, another poster on this forum has a system that has no thermostat, only a well-tuned reset curve, hard-wired to always be calling for heat.)

When you insulate the basement and tighten the place up it takes hours of 0F outside temp to drop from 70F down to 60F. In the event of an extended power outage it doesn't really matter how big the boiler is.

Just fer yuks, try pretending that you actually live in a first-world country, where power outages that go more than a few minutes are relatively rare. If it turns out that your local grid is connected to some third-world hell and you lose power daily or for days/weeks at a time, buy a generator. Grid reliability in the US isn't quite as good as western Europe, but it's not Uganda or Afghanistan either.

I say this as someone who was out of power for 10 days after a major ice storm in December 2010 when temps were dropping to 10F every other night: I still wouldn't oversize a mod-con by 2-3x just so the recovery ramp after a power loss in the dead of winter ran a bit faster, nor would I oversize it to be able to use deep setbacks.

And in fact, my current heating system's DOE capacity is less than 1.25x the heat load at my 99% outside design temp, and it still keeps up when it's 10-15F colder than the outside design temp. Below that I might have to think about leaving the lights on or firing up the wood stove, but I'd be good down into the -30s F with any amount of auxiliary heating, a temp not seen here since record keeping began. Yes, on the hydro-air zone controlled with setback the recovery ramps from a 5F setback are pretty long (2-3 hours) when it's colder than the outside design temp, but so what?

The pipe losses are still all inside the house- they're not lost, they're just in the basement, warming up the underside of your first floor. The majority of those losses are still accruing to the heat load even before you insulate the foundation. After you insulate the basement the number of pipe loss BTUs that actually escaped the basement will have dropped by an order of magnitude or so.

With a mod-con you don't really want do use deep setbacks, since that would require higher water temps (= lower efficiency). When you dial in the outdoor reset curve to where the thermostats are (almost) never satisfied but it never loses ground, you will use less fuel than you might have saved with any overnight setback scheme due to the higher efficiency. (IIRC BadgerBoilerMN, another poster on this forum has a system that has no thermostat, only a well-tuned reset curve, hard-wired to always be calling for heat.)

When you insulate the basement and tighten the place up it takes hours of 0F outside temp to drop from 70F down to 60F. In the event of an extended power outage it doesn't really matter how big the boiler is.

Just fer yuks, try pretending that you actually live in a first-world country, where power outages that go more than a few minutes are relatively rare. If it turns out that your local grid is connected to some third-world hell and you lose power daily or for days/weeks at a time, buy a generator. Grid reliability in the US isn't quite as good as western Europe, but it's not Uganda or Afghanistan either.

I say this as someone who was out of power for 10 days after a major ice storm in December 2010 when temps were dropping to 10F every other night: I still wouldn't oversize a mod-con by 2-3x just so the recovery ramp after a power loss in the dead of winter ran a bit faster, nor would I oversize it to be able to use deep setbacks.

And in fact, my current heating system's DOE capacity is less than 1.25x the heat load at my 99% outside design temp, and it still keeps up when it's 10-15F colder than the outside design temp. Below that I might have to think about leaving the lights on or firing up the wood stove, but I'd be good down into the -30s F with any amount of auxiliary heating, a temp not seen here since record keeping began. Yes, on the hydro-air zone controlled with setback the recovery ramps from a 5F setback are pretty long (2-3 hours) when it's colder than the outside design temp, but so what?

Here's the anti-climax: the kitchen renovation budget is eating the boiler replacement budget, so I think Beads' "what's the rush?" is going to carry the day. I was hoping to have everything done by move-in, but that's not going to happen. On the bright side, this will give me real usage numbers to work with. Many thanks, particularly to you, Dana, for helping me figure this out. I'll be back down the road with more info.

Major renovations are opportunity moments for improving the thermal efficiency of the building envelope, and for inspecting how the building is doing in general from a moisture resilience point of view.

If you're gutting any exterior walls, take the time to air-seal the framing to the sheathing, and go better than code on cavity-R (if you can.)

In kitchens high-density rock wool carefully fitted & installed can be worth it from a fire-resistance point of view alone.

Don't install polyethylene vapor barriers unless you have ample drying capacity toward the exterior (which sometimes takes a bit of investigation to figure out. Concentrate more on making the interior side finish air-tight- one square inch of air leakage moves far more moisture into the wall in winter than a whole wall's worth of vapor diffusion through latex-painted wallboard.

If you're gutting any exterior walls, take the time to air-seal the framing to the sheathing, and go better than code on cavity-R (if you can.)

In kitchens high-density rock wool carefully fitted & installed can be worth it from a fire-resistance point of view alone.

Don't install polyethylene vapor barriers unless you have ample drying capacity toward the exterior (which sometimes takes a bit of investigation to figure out. Concentrate more on making the interior side finish air-tight- one square inch of air leakage moves far more moisture into the wall in winter than a whole wall's worth of vapor diffusion through latex-painted wallboard.

BadgerBoilerMN

Hydronic Heating Designer

This horse is dead.

Triangle Tube 60 is all that the 96 feet of baseboard can serve and the perfect match for the Smart 40. We have many on similar houses hear in Minneapolis. 15-25% fuel savings is reason enough to through out the old cast iron anchor.

The VersaHydro is grand but not my first choice on a straight fin-tube design. If the micro-zone in the basement wants to call by itself cut the end switch out.

I could do a Manual J for you, but it costs more than $100.00 and Dana already did it in his head!

Triangle Tube 60 is all that the 96 feet of baseboard can serve and the perfect match for the Smart 40. We have many on similar houses hear in Minneapolis. 15-25% fuel savings is reason enough to through out the old cast iron anchor.

The VersaHydro is grand but not my first choice on a straight fin-tube design. If the micro-zone in the basement wants to call by itself cut the end switch out.

I could do a Manual J for you, but it costs more than $100.00 and Dana already did it in his head!

Actually, I did a straw-man hack of an I=B=R calc in a previous post, but that combined with the poorly done manual-J with a few corrections is good enough for the boiler sizing.

Before the time comes, a fuel-use against heating degree-day calc using the existing beastie boiler as the measuring instrument would be a good sanity check.

Before the time comes, a fuel-use against heating degree-day calc using the existing beastie boiler as the measuring instrument would be a good sanity check.

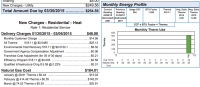

Ok, at last, we have a gas bill. The February number from degreedays.net for our weather station is 1306, and according to the gas bill, we used 414.49 therms that month (BTU factor is 1.028). The house was unoccupied most of that time and set to somewhere in the 68-70 degree range (I kept it warm to get a realistic gas bill). One hiccup: some workmen turned off the heat one day and forgot to turn it back on, and we had a frozen/burst pipe, so for about 12 hours the heat was off entirely and for about 12 hours it was cranked to maximum. The boiler is 160/128. Do I have all the info I need to make a calculation?

You need to report if this was an estimated bill, or if last month was an estimated bill. If they only read the meter every other month, it is more complex.Ok, at last, we have a gas bill. The February number from degreedays.net for our weather station is 1306, and according to the gas bill, we used 414.49 therms that month (BTU factor is 1.028). The house was unoccupied most of that time and set to somewhere in the 68-70 degree range (I kept it warm to get a realistic gas bill). One hiccup: some workmen turned off the heat one day and forgot to turn it back on, and we had a frozen/burst pipe, so for about 12 hours the heat was off entirely and for about 12 hours it was cranked to maximum. The boiler is 160/128. Do I have all the info I need to make a calculation?

Similar threads

- Replies

- 2

- Views

- 562

- Replies

- 4

- Views

- 499

- Replies

- 11

- Views

- 1K