Two more questions before I tackle the meter assembly on Monday.

First,

I suspect that this may be related to my current problem.

On about 5 or 6 occasions our water supply has slowed to a trickle. In order to fix the problem, I've done the following:

1. shut off the water supply at the source

2. opened a tap upstream from the softener (to create reverse pressure at the softener), then shut off the tap

3. turned on the water supply

This has fixed the problem. Apparently, there is a flow restrictor in the softener (3.5 USGPM) to ensure that the tannin removal process doesn't get overwhelmed. I've rationalized that there has been a small piece of solder or other impurity that has become stuck in this restrictor. Once the pressure has been reversed slightly, the impurity has become dislodged and water flow returned to normal.

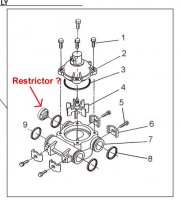

Once I have the meter assembly taken apart, I'd like to examine this restrictor just in case my rationalization is correct. However, I can't find anything called a restrictor on the exploded parts diagram. I suspect that it is the unnamed part on the diagram on page 18 of the manual that Reach4 and Akpsdvan supplied. (diagram attached)

Is this the restrictor?

Second,

There is only a very short distance between the meter assembly and the floor above. In order to properly examine the impeller, as Akpsdvan suggested I'll need to "un hook it between the meter housing and the bypass and then undo the collar that holds the valve to the tank adapter and move the assembly forward and down". I don't have a lot of room above the meter assembly to lift it off once unhooked. I can't see this on the exploded parts diagram, but I suspect that the meter assembly has to be connected to a couple of pipes inside the resin tank so that the water can be pushed through the resin. I'm worried that there may no be enough clearance above the softener to lift the assembly off these pipes. Part number 6 on page 15 of the exploded parts diagram looks like it might be 1"-2" deep but it looks like it only has one outlet/inlet and I'd rationalize the the system would need 2. (one input, one output). Therefore, can anyone give me a better idea of how the meter assembly is connected inside the resin tank?

Thank-you in advance! You guys have been amazing with all your help!!!!!!